These dryers use desiccants (like alumina activa, silica gel….etc.) which adsorbs the water vapor in the air stream desiccant type dryer.

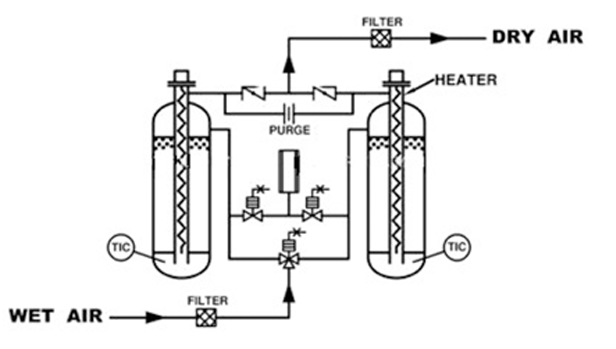

Regenerative desiccant dryers normally are of twin tower construction. One tower dries the air from the compressor while the desiccant in the other tower is being regenerated after the pressure in the tower has been reduced to atmospheric pressure. Regeneration can be accomplished using a time cycle or on demand by measuring the temperature or humidity in the desiccant towers or by measuring the dew point of the air leaving the on-line tower.

In the heatless regenerative desiccant type, no internal or external heaters are used. Purge air requirement can range up to 18% of the total air-flow. The typical regenerative desiccant dryer at 100 psig has a pressure dew point rating of -40°F but dew points down to -100°F can be obtained.

- Very low dew points can be achieved without potential freeze-up.

- Moderate cost of operation for the dew points achieved.

- Low maintenance costs.

- Heatless type can be designed to operate pneumatically for remote, mobile or hazardous locations.